News

December 8, 2023: The actual measured on-off life of the Lang Valve DN50 clamp valve has exceeded 1.4 million times.

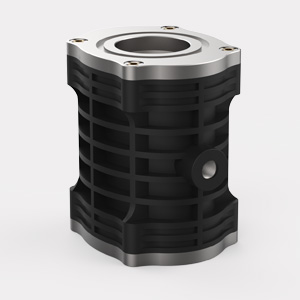

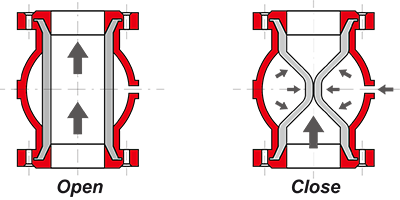

On December 8, 2023, Shanghai Lang Valve Machinery Co., Ltd. announced the life test results of ATP-DN50, with the number of on-off cycles exceeding 1.4 million times. This life test of the clamp valve lining was conducted using the ATP series valve body with a diameter of DN50, to meet the special requirements of the train vacuum toilet system for the life of the on-off cycles. The aspect ratio of this series of clamp valves is relatively small, and the linings are subjected to greater tensile and bending forces compared to other series. Therefore, the breakthrough improvement in the on-off life of the ATP series clamp valves means a disruptive improvement in the life of the linings of all series of Lang Valve clamp valves. This is another important milestone after the ATP-DN15 clamp valve was tested to 2.6 million cycles five years ago.

The minimum air pressure for closure in this test was 0.26MPa; the working air pressure for the life test was 0.45MPa; that is, the life in the actual working state (with air pressure between 0.26 and 0.45MPa) will be greater than the tested life.

The vacuum toilet system introduced from abroad for China’s CRRC is equipped with a DN50 clamp valve, with a nominal life of 400,000 cycles. The experimental results of Lang Valve have laid an important foundation for the improvement of the technical standards of CRRC’s clamp valves.

Why choose LV?

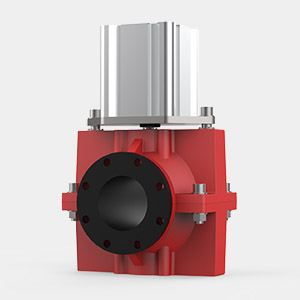

Full range of products

- LV has 30 product categories

- According to the operation mode, it can be divided into pneumatic, manual and electric

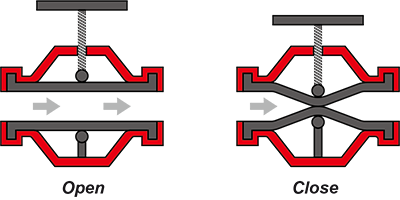

- According to the working principle, it can be divided into air direct compression type and lever extrusion type

Full of Customized

The pinch valve at LV can be customized according to the following requirements

- Size and material, transmission medium, service life, working temperature, working pressure, working environment

Functional rubber laboratory

According to the use environment under various working conditions, the rubber formula of inner bushing can be independently developed, and strict pressure, temperature and life tests can be carried out to meet the use needs of customers

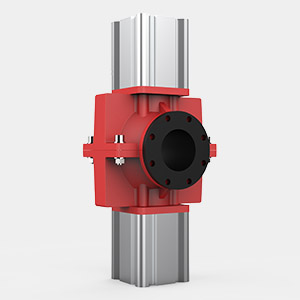

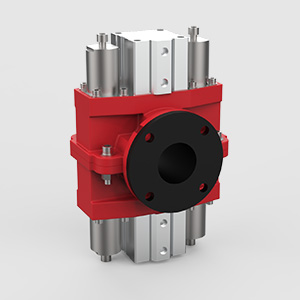

Air direct-pressure pinch valve

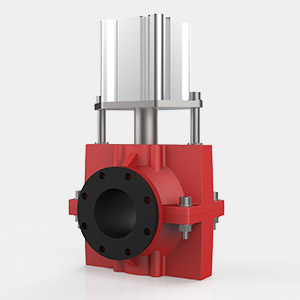

Lever squeeze pinch valve