Technology and application of pinch valve

1、Characteristics of air direct-pressure pinch valve and lever extrusion pinch valve

The working principle of the pinch valve is to squeeze and deform the elastic materials such as rubber, which are part of the pipeline, to block the pipeline under human control, to prevent the flow of the medium in the pipeline, and to play the function of the valve.

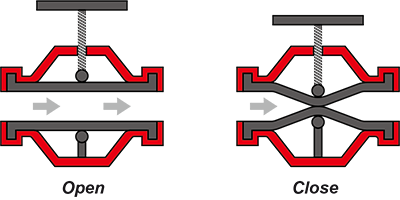

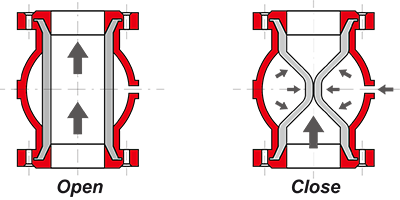

The elastic material in the pinch valve is called the inner bushing, which can be divided into two types according to the different methods of pressing and closing the inner bushing, namely, the air direct pressing type and the lever pressing type, as shown in the figure.

The two ends of the rubber inner sleeve in the air direct-pressure pinch valve are connected with the pipeline, and become a part of the material delivery pipeline. The two ends of the inner bushing and the two ends of the can-shaped valve body are extruded and assembled in a closed manner, and an annular gas chamber is formed between the inner wall of the can-body of the pinch valve and the outer wall of the inner bushing. When the air chamber is filled with compressed air, the compressed air compresses and deforms the inner bushing to close the channel; After venting, the inner bushing returns to the conduction state by its own elasticity. The air direct-pressure pinch valve is characterized by a large area of flexible closure, and has the bionic effect of animal organs. It has more advantages in the case that the conveying medium contains solids with uncertain shape and size.

The two ends of the rubber inner sleeve in the lever-extruded pinch valve are connected with the pipeline and become a part of the material delivery pipeline. The middle two sides of the inner bushing are equipped with extrusion levers. When the upper and lower levers are pressed together, the pinch valve will be flattened to close the channel; The channel opens after the lever is released. The extrusion lever can be driven by manpower (hand wheel drives screw), compressed air (cylinder) and electric power (electric actuator) to realize the extrusion action. The feature of the lever squeeze type pinch valve is that it is easy to realize forced closing for applications with high pipeline pressure; Through the additional device, the forced self-locking closing of the pinch valve can be realized under accident conditions (gas failure, power failure); The valve opening is controlled by pneumatic positioner; Accurate flow control is achieved through electric actuators.

2、Selection principle of pinch valve

Customers choose pinch valves as valves for various reasons. When designing or purchasing pinch valves, according to our experience, it is recommended to select the series or specifications suitable for your requirements according to the following sequence:

- Select manual drive (i.e. manual) or active power drive according to the drive mode. Active power drive is divided into pneumatic or electric; The pneumatic mode is divided into two types: direct air compression and cylinder driven lever extrusion.

- The valve body materials, such as plastic, aluminum alloy, carbon steel and stainless steel, shall be selected according to the use environment and working conditions.

- The inner bushing material shall be selected according to the characteristics of the transmission medium in the pipeline, and the factors to be considered include pressure resistance, wear resistance, corrosion resistance, etc.

- Other special requirements to be considered:

- Anti-static requirements for inner bushing.

- Control the adjustment function of the opening of the pinch valve.

- Self-locking function of automatic closing of pinch valve in case of accident.

- A manual auxiliary function is installed on the power-driven pinch valve.

- Special structural design requirements when the installation space is limited.