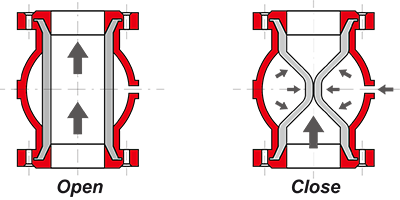

Brief introduction of air direct-pressure pinch valve

The working principle of the air direct-pressure pinch valve is shown in the figure. The two ends of the rubber inner sleeve inside the pinch valve are connected with the pipeline and become a part of the material delivery pipeline. The two ends of the inner bushing and the two ends of the can-shaped valve body are extruded and assembled in a closed manner, and an annular gas chamber is formed between the inner wall of the can-body of the pinch valve and the outer wall of the inner bushing. When the air chamber is filled with compressed air, the compressed air compresses and deforms the inner bushing to close the channel; After venting, the inner bushing returns to the conduction state by its own elasticity.

The air direct-pressure pinch valve is characterized by a large area of flexible closure, and has the bionic effect of animal organs. It has more advantages in the case that the conveying medium contains solids with uncertain shape and size.

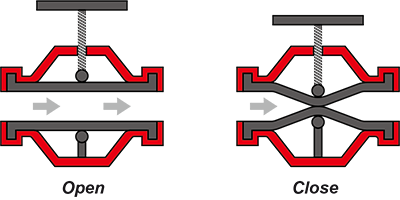

Brief introduction of lever extrusion pinch valve

The working principle of the lever-extruded pinch valve is shown in the figure. The two ends of the rubber inner sleeve inside the pinch valve are connected with the pipeline and become a part of the material delivery pipeline. The middle two sides of the inner bushing are equipped with extrusion levers. When the upper and lower levers are pressed together, the pinch valve will be flattened to close the channel; The channel opens after the lever is released. The extrusion lever can be driven by manpower (hand wheel drives screw), compressed air (cylinder) and electric power (electric actuator) to realize the extrusion action.

The feature of the lever squeeze type pinch valve is that it is easy to realize forced closing for applications with high pipeline pressure; Through the additional device, the forced self-locking closing of the pinch valve can be realized under accident conditions (gas failure, power failure); The valve opening is controlled by pneumatic positioner; Accurate flow control is achieved through electric actuators.

Brief introduction of inner sleeve of pinch valve

The inner sleeve is the core component of the pinch valve, which determines the quality and performance of the pinch valve.

Inner bushing classification:

According to the structure, it can be divided into three types: straight barrel type, half flange type, full flange type and special structure.

- It is divided into natural rubber, NBR, EPDM, silicone rubber, neoprene, fluororubber, composite materials, etc.

- According to mechanical strength, it can be divided into (in pipe) high pressure and low pressure.

- It is divided into high pressure type and low pressure type according to closing performance.

- It is divided into food grade and non-food grade according to the hygienic standard.